We have been designing, manufacturing and installing industrial filter presses since 1977

Filtri Fazzini

Filtri Fazzini was founded at the end of 1977, the year in which the Merli Law, which protected water from pollution by regulating industrial discharges of all kinds, was passed.

The problems related to pollution from urban, industrial or chemical waste were many and their management risked becoming an out-of-control problem.

One of the main concerns in this respect was precisely the disposal of pollutants in waste water, whether organic, inorganic or recycled.

It was from this need and from the resourcefulness of Gabriele Fazzini that our company was born. We began to study, design and produce plate filter presses that allow pressure dewatering and solid-liquid separation of industrial sludge previously treated in biological and, above all, chemical and physical wastewater treatment plants.

Today Filtri Fazzini is led by his son Fabio Fazzini, who ensures the continuity of the business by keeping it up to date with technological advances while preserving the family tradition.

Almost 50 years of experience

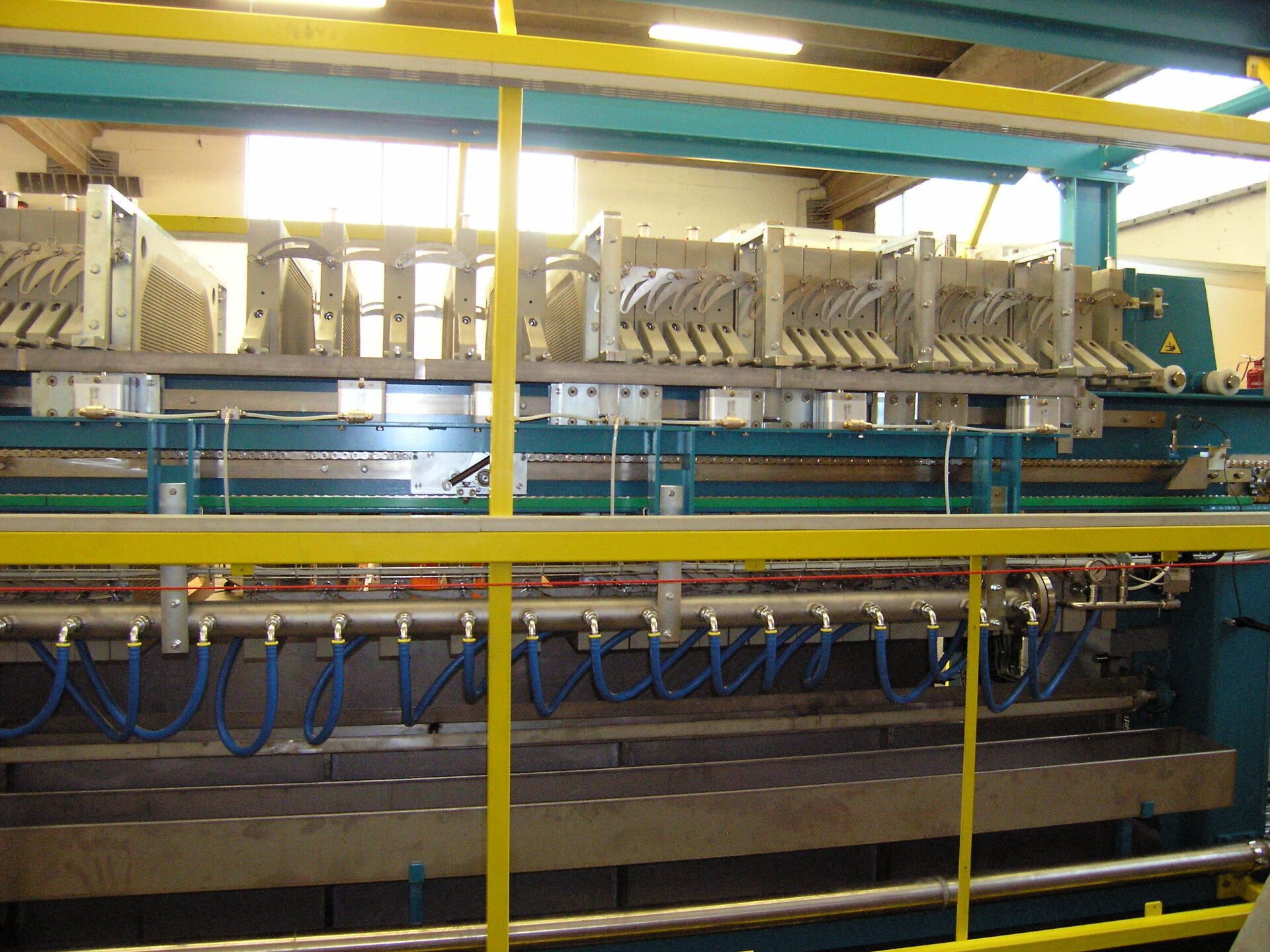

Filtri Fazzini has been designing, manufacturing and installing industrial filter presses since 1977.

Thanks to our experience, we guarantee comprehensive consultancy and analysis in project development, ultimately producing only customised machines tailored to the customer's needs.

Over the years, Filtri Fazzini has become a point of reference in the field of industrial ecology and has established itself as a leading company in the design and manufacture of plate filter press systems, enhancing and expanding its fleet of machines: with manual, semi-automatic and fully automatic machines that do not require an operator.

In-house design and production

Thanks to its craftsmanship character, which has been strongly desired and defended over the years, Filtri Fazzini is still able to satisfy any market demand.

By manufacturing entirely in its own factories, it can thus follow and customise every stage of processing.

In particular, the company's size allows it to take meticulous care in satisfying every customer request, thus guaranteeing the highest level of customisation and the certainty of always dealing with the same contact person.

Applications

of Filter Presses

Filter presses filter water in industrial processes in two main ways:

filtration from purification and filtration from process.

Filtration from purification

which is necessary at the end of the production process, to separate solid or polluting particles in the wastewater delivered to the treatment plant for immediate biological or chemical-physical treatment, so as to ensure the quality and safety of the water released into the environment.

Filtration from process

which comes into action during the production process of the industrial plant and which has a double strategic role of retaining the noble particles that are already in the waste water and filtering the process water for the production cycles.

The applications of FAZZINI Filter Presses thus play a major role on two fronts:

in protecting the environment and benefiting the industrial process. They enable all industrial and/or commercial operators, be they private engineering companies or public bodies, to find the best solutions to the problems of polluting waste (liquid and semi-liquid) and the recycling of reusable substances, providing considerable benefits while protecting and preserving the natural environment in which we live.